WHY CHOOSE RAMA?

RAMA srl is a company that designs and manufactures machines and equipment for packaging. RAMA is committed to innovation and the use of the most advanced technologies, which makes our machines of a high standard quality. Thanks to RAMA’s highly specialized team, we are able to provide complete lines with a high performance as a consequence.

For privacy reasons YouTube needs your permission to be loaded.

I AcceptOUR PACKAGING LINES CAN BE COMPOSED OF:

Products

News

News, updates, curiosities and events related to Rama

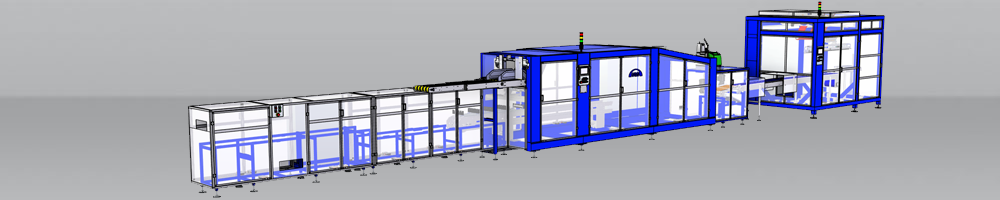

AUTOMATIC LINE FOR FROZEN PIZZAS

3s-admin2020-05-08T11:51:32+02:00May 8th, 2020|

Coffee capsules multiple pack

3s-admin2020-05-08T11:42:09+02:00May 8th, 2020|

A PLASTIC FREE CHOICE FOR BEVERAGE CANS PACKAGING

3s-admin2021-03-03T11:12:34+01:00May 8th, 2020|